In order to guarantee our product quality, we pay much attention to the below three procedures strictly;

First, we introduced advanced manufacturing and inspection requipments.

Second, we train every operator strictly and make sure that he has got the certificate to operating manufacturing, we inspect each producing procedures strictly. From purchasing the raw material to sell and every process is according to the standard requirements.

Third, we establish sound quality control system to ensure every operation conforms to standard. There is always a well-trained inspector for quality control from the purchasing of raw materials to after sales services. We have got the certificate of ISO9001.

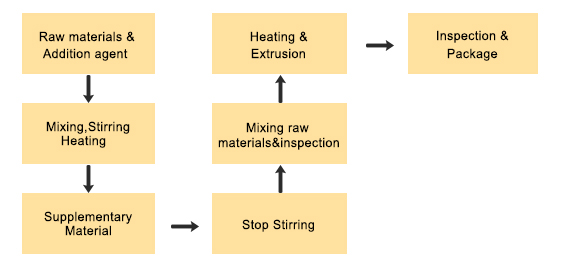

Technical Flow of PVC Compound

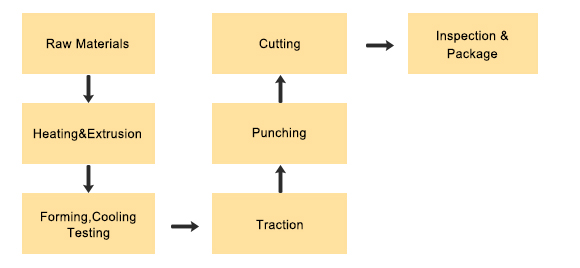

Technical Flow of Extrusion Profile & Quality Control

Technical Flow of Extrusion Profile

Quality control of the production process:

Preliminary inspection: workers inspect the new products of its straight, smooth and so on.

Re-examination: Inspectors with special tools test products on the production line from time to time. According to confirming sample of customer, inspector tests various indicators including length, width, thickness, hardness, angle, color and etc.

Spot Checks: Before packaging, quality control department will do spot checks, including product size, color, hardness, packaging materials, quantity, etc. After strictly examined, we make sure provide customers qualified and satisfied Products.